SANITARY PUMPS

Technical Specifications:

Flow Rate:1-500m³/h

Head Range:1m-100m(0.1-10bar)

Material: SUS304, SUS316L Contact Parts

The company focuses on international cooperation, introduces advanced processing equipment, and maintains professional technical background and resources. It can provide technical parameters and ISO, IDF, DIN, ASME-BPE, SMS, 3A industrial standard manufacturing and OEM services according to customer requirements. The products comply with GMP requirements and are produced in strict accordance with the requirements of ISO9001 international quality system.

Dedicated to provide you with: solutions and innovative solutions such as sanitary pumps, maintenance inspection management, system efficiency services, technical consultation and transformation.

1. Hygiene standards: Sanitary valve complies with the relevant sanitary standards in the field of health engineering and food manufacturing,

2. Preventive pollution design: Sanitary valve adopts non -dead corner design to avoid pollutants staying and breeding bacteria

3. Easy to clean: The internal surface of the sanitary valve is smooth, easy to clean and reduce cleaning time and labor cost

4. High -density: Sanitary valve has good sealing performance to ensure that the fluid is not leaked.

Applicable range:

1. Food and beverage industry: Hygienic valves are used for food processing, liquid transportation, and filling to ensure the hygiene quality of the product.

2. Pharmaceutical industry: Sanitary valves are used to control the flow of drugs in pharmaceutical production and ensure the purity and efficacy of the product.

3. Biological engineering: Sanitary valve for biological reactor, cell culture and fermentation process to ensure the quality of biological products

Medical Device: Sanitary valves are used in medical devices, such as infusion

4. Equipment, blood treatment equipment, etc. to ensure the hygiene of the medical process

5. The brewing industry: The hygiene valve is used for liquid control during winemaking to ensure the quality of winemaking products.

1. Good material: Health pipelines are usually made of high -quality materials such as stainless steel and nickel -based alloy. It has the characteristics of corrosion resistance, high temperature resistance, and pressure resistance, which can meet the strict industrial environment requirements.

2. Surface smoothness: The surface of the hygiene -grade pipes is polished, and there is no obvious burrs and unevenness, which can effectively prevent bacteria from breeding and facilitated cleaning.

3. Good sealing: Sanitary pipelines adopt professional sealing structure design, which can effectively prevent leakage and pollution and ensure the purity of fluids in pipelines.

4. Easy to disassemble: Sanitary tube parts usually adopt a fast connector or spiral connection method, which is convenient for disassembly and cleaning, saving time and labor costs.

5. High reliability: After strict quality testing, sanitary pipelines have stable performance and reliable quality assurance, and can run stable for a long time.

Applicable range:

1. Food industry: Health pipelines are widely used in pipeline systems in food processing, brewing, dairy products and other industries. They can ensure that food is not contaminated during the processing and maintains its original nutrition and taste.

2. Pharmaceutical industry: Health pipelines play a vital role in the pharmaceutical industry. They can ensure that drugs are not polluted during the production process and their purity and effectiveness are ensured.

3. Chemical industry: Health pipelines are also widely used in chemical industry, such as chemical reactors, conveying pipelines, etc. They have the characteristics of corrosion resistance, high temperature resistance, pressure resistance, and can meet complex chemical transportation needs.

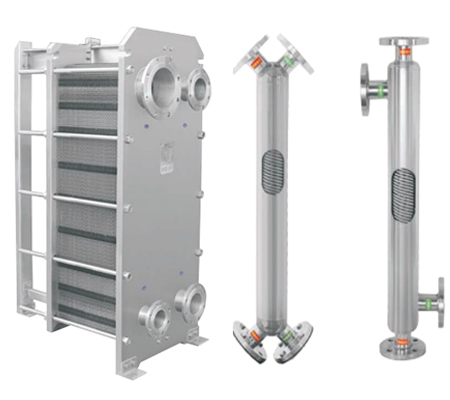

1. Safe and stability: 1) The surface of the high -precision polishing pipe is smooth and uniform. The diameter of the tube is small, the material and the cold/heat media flow rate is high, and the turbulence is formed. The tube is easy to clean, which can greatly reduce the probability of the formation of the biofilm. 2) Reasonable design and even welding can be reduced. Due to the different tube/shell expansion coefficients, the risk of leakage is caused (some products are forced to install the expansion section to reduce this risk)

2. High heat exchange efficiency: The heat exchanger adopts advanced diversion structure design to make the diversion uniform. The unique diversion structure allows the medium to evenly allocate the traffic on the entire plate to improve the heat transfer efficiency

3. Convenient for heat exchanger operation and maintenance: The heat exchanger is installed close to the practical point, easy to disassemble, all card holes and valves, the operator’s single operation, the tentacles can be within reach, no need to use the tools, escalators.

Applicable range:

1. Food and beverage: raw juice heating, fruit paste heating, carbonate juice heating, syrup cooling, thin fruit juice heating, concentration of fruit juice, milk and soy milk heating and cooling, Basal sterilization, CIP cleaning and beer technology.

2. Seasoning: Heating and cooling of edible oil, cooling, soy sauce, vinegar, fuel consumption, tomato sauce and chili sauce heating, cooling and residual heat recovery.

3. Pharmaceuticals: lotion cooling, suspension heating, heating of plasma, heating of plasma, citric acid heating, infusion cooling, gas condensation, fermentation solution cooling and vitamin process.

The products are widely used in equipment supporting fields such as biopharmaceuticals, beer, wine, Baijiu, dairy products, food, beverages, ice cream, water treatment, cyclic evaporation concentration, fine chemicals, etc. More than 7000 pumps can be produced annually, and standard products are in stock for quick supply. Get a Quote

The product meets GMP requirements and is strictly produced in accordance with the ISO9001 international quality system requirements. Provide you with solutions and innovative solutions for sanitary pumps.

The products are widely used in equipment supporting fields such as biopharmaceuticals, beer, wine, Baijiu, dairy products, food, beverages, ice cream, water treatment, cyclic evaporation concentration

The business policy of continuous improvement is to meet the high-end requirements of domestic and foreign customers with high-quality products and services.