SELF-PRIMING PUMP

Spec: 5T-80T, 2.2KW-15KW

Shut-Off Valve is used in dairy, food, beverage production, bio-pharmaceutical, fine chemical, water treatment, new energy and other industries. The valve controls various fluid flows, temperatures, pressures, and so on.

The valves are used in automation and contronl systems,tocontronl the pressure,flow,level,temperature,and the tank level.

Structural form:

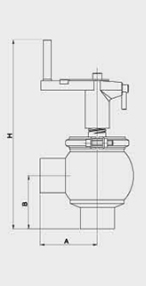

YJS Handle Globe Valve:

| DIN | 3A | SMS | SO | A | B | H |

| DN15 | 3/4″ | 19 | φ19 | 67 | 63 | 234 | |

| DN20 | 1″ | 25 | φ25 | 67 | 63 | 234 | |

| DN25 | 32 | φ32 | 67 | 63 | 234 | ||

| DN32 | 11/2″ | 38 | φ38 | 67 | 63 | 234 | |

| DN40 | 67 | 63 | 234 | ||||

| DN50 | 2″ | 51 | φ51 | 67 | 63 | 234 |

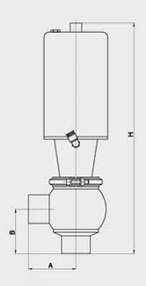

YJQ Pneumatic Globe Valve:

| DIN | 3A | SMS | ISO | A | B | H |

| DN15 | 3/4″ | 19 | φ19 | 67 | 63 | 357 | |

| DN20 | 1″ | 25 | φ25 | 67 | 63 | 357 | |

| DN25 | 32 | φ32 | 67 | 63 | 357 | ||

| DN32 | 11/2″ | 38 | φ38 | 67 | 63 | 357 | |

| DN40 | 67 | 63 | 357 | ||||

| DN50 | 2″ | 51 | φ51 | 67 | 63 | 357 | |

| 21/2″ | 63 | φ63 | 86 | 83 | 394 |

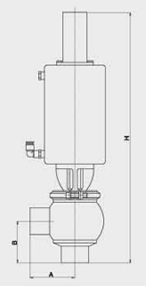

YJX Pneumatic Globe Valve:

| DIN | 3A | SMS | ISO | A | B | H |

| DN15 | 3/4″ | 19 | φ19 | 58 | 58 | 400 | |

| DN20 | 1″ | 25 | φ25 | 58 | 58 | 400 | |

| DN25 | 32 | φ32 | 58 | 58 | 400 | ||

| DN32 | 11/2″ | 38 | φ38 | 58 | 58 | 400 | |

| DN40 | 58 | 58 | 400 | ||||

| DN50 | 2″ | 51 | φ51 | 63 | 65 | 420 | |

| 21/2″ | 63 | φ63 | 79 | 82 | 453 |

Application:

The valves are used in automation and contronl systems,tocontronl the pressure,flow,level,temperature,and the tank level.

Working principle:

The pneumatic stop valve can convert the energy generated by compressed the air to mechanical energy ,the merchanical energy can drive the stem axial movement ,therefore mover the sealing components in drfferent places,then can contronl the open or close of the mouth of pipe ,then achieve the purpose of change the direction of medium or keep the midum stay The manual stop valve sery operated by manualhandle ,and ultimate purpose is to change the direction of the medium or keep the medium stay .

Valve Material

Contact with products parts :304 or 316L

Valve core seal selection

Soft seal:EDPM or PTFE

Metal seal

Surface treatment

Surface treatment: Sandblasting Ra≤1.6um ; cast Sub-light Ra≤0.6um

Inside Surface treatment: Polishing Ra≤0.6um