PIPE HOLDER

Used in industrial fields such as dairy, food and beverage, beer, biopharmaceuticals and daily chemicals

1. Good material: Health pipelines are usually made of high -quality materials such as stainless steel and nickel -based alloy. It has the characteristics of corrosion resistance, high temperature resistance, and pressure resistance, which can meet the strict industrial environment requirements.

2. Surface smoothness: The surface of the hygiene -grade pipes is polished, and there is no obvious burrs and unevenness, which can effectively prevent bacteria from breeding and facilitated cleaning.

3. Good sealing: Sanitary pipelines adopt professional sealing structure design, which can effectively prevent leakage and pollution and ensure the purity of fluids in pipelines.

4. Easy to disassemble: Sanitary tube parts usually adopt a fast connector or spiral connection method, which is convenient for disassembly and cleaning, saving time and labor costs.

5. High reliability: After strict quality testing, sanitary pipelines have stable performance and reliable quality assurance, and can run stable for a long time.

Applicable range:

1. Food industry: Health pipelines are widely used in pipeline systems in food processing, brewing, dairy products and other industries. They can ensure that food is not contaminated during the processing and maintains its original nutrition and taste.

2. Pharmaceutical industry: Health pipelines play a vital role in the pharmaceutical industry. They can ensure that drugs are not polluted during the production process and their purity and effectiveness are ensured.

3. Chemical industry: Health pipelines are also widely used in chemical industry, such as chemical reactors, conveying pipelines, etc. They have the characteristics of corrosion resistance, high temperature resistance, pressure resistance, and can meet complex chemical transportation needs.

Used in industrial fields such as dairy, food and beverage, beer, biopharmaceuticals and daily chemicals

Used in food, beverage, biotech, pharmaceutical and all other sanitary process industries

Used in industrial fields such as dairy, food and beverage, beer, biopharmaceuticals and daily chemicals

5000 square meters

3-5 days

Each process undergoes quality inspection and testing before leaving the factory.

We provide users with reliable and assured protection with high-quality services, fast after-sales timeliness, and an attitude of paying attention and caring to users.

There is currently no agent, our factory is in Wenzhou, China

Product quality management standards: The production of mechanical products needs to comply with the relevant quality management standard ISO 9001 (quality management system).

50 people

Can produce customized products and OEM processing.

Yes, please contact our staff email to obtain it.

The valve is leaking, or the pipeline installation is unreasonable. Check the sealing ring of the outlet check valve or take a video of the installation.

One year for the motor and 6 months for the mechanical seal wearing parts

the pump does not run during sterilization. A single machine seal is sufficient.

-0.095MPA is no problem

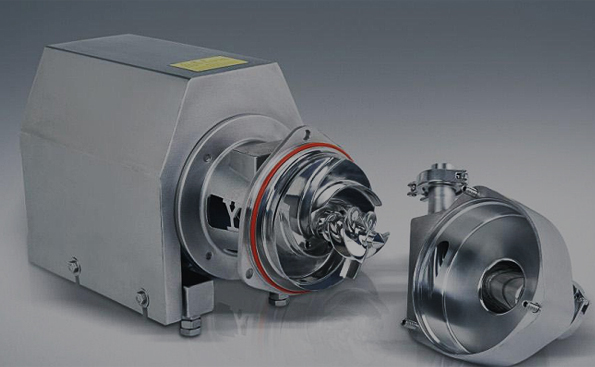

Negative pressure pump centrifugal pump materials include 304, 316L, 2205, titanium 2 (TA2)

The dynamic and static rings are graphite/silicon carbide, the mechanical seal ring is fluororubber, and the pump head sealing ring is silicone

Just insert the Φ8 leather tube.

High precision fluid equipment production enterprise!