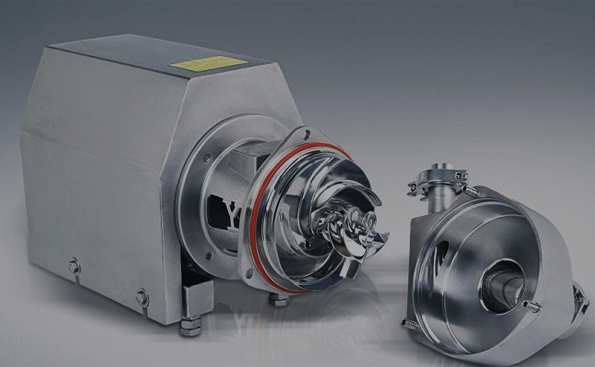

CHECK VAVLE

Check valve is designed to prevent fluid from flowing back and ensure the flow to one way direction.

1. Hygiene standards: Sanitary valve complies with the relevant sanitary standards in the field of health engineering and food manufacturing,

2. Preventive pollution design: Sanitary valve adopts non -dead corner design to avoid pollutants staying and breeding bacteria

3. Easy to clean: The internal surface of the sanitary valve is smooth, easy to clean and reduce cleaning time and labor cost

4. High -density: Sanitary valve has good sealing performance to ensure that the fluid is not leaked.

Applicable range:

1. Food and beverage industry: Hygienic valves are used for food processing, liquid transportation, and filling to ensure the hygiene quality of the product.

2. Pharmaceutical industry: Sanitary valves are used to control the flow of drugs in pharmaceutical production and ensure the purity and efficacy of the product.

3. Biological engineering: Sanitary valve for biological reactor, cell culture and fermentation process to ensure the quality of biological products

Medical Device: Sanitary valves are used in medical devices, such as infusion

4. Equipment, blood treatment equipment, etc. to ensure the hygiene of the medical process

5. The brewing industry: The hygiene valve is used for liquid control during winemaking to ensure the quality of winemaking products.

Check valve is designed to prevent fluid from flowing back and ensure the flow to one way direction.

Valve body material:AISI 316L(1.4404)ASME BPE 316L

Spec: 1T-500T,0.55KW-75KW

Seal material: Polyfluoro Tetraethylene PTFE

Applied to the food processing, beverage, pharmaceutical, and other areas of the pipeline system

Used to diary, food processing, beverage,pharmaceutical and fine chemical industries.

Used to protect the pressure flowing through pipes, pumps, accessories, pools, etc

Used to transfer the material The range of application including food,beverage processing ,medicine and chemical industry area

Used in food processing, pharmaceutical and chemical products, industrial fluid applications.

Used in biopharmaceutical fluid control system.

Used in dairy, food, beverage production, bio-pharmaceutical, fine chemical, water treatment, new energy and other industries

Material contact parts :304 or 316L

5000 square meters

3-5 days

Each process undergoes quality inspection and testing before leaving the factory.

We provide users with reliable and assured protection with high-quality services, fast after-sales timeliness, and an attitude of paying attention and caring to users.

There is currently no agent, our factory is in Wenzhou, China

Product quality management standards: The production of mechanical products needs to comply with the relevant quality management standard ISO 9001 (quality management system).

50 people

Can produce customized products and OEM processing.

Yes, please contact our staff email to obtain it.

The valve is leaking, or the pipeline installation is unreasonable. Check the sealing ring of the outlet check valve or take a video of the installation.

One year for the motor and 6 months for the mechanical seal wearing parts

the pump does not run during sterilization. A single machine seal is sufficient.

-0.095MPA is no problem

Negative pressure pump centrifugal pump materials include 304, 316L, 2205, titanium 2 (TA2)

The dynamic and static rings are graphite/silicon carbide, the mechanical seal ring is fluororubber, and the pump head sealing ring is silicone

Just insert the Φ8 leather tube.

High precision fluid equipment production enterprise!